Setting Up and Troubleshooting Microplate Readers for ELISA Assays

Setting Up and Troubleshooting Microplate Readers for ELISA Assays

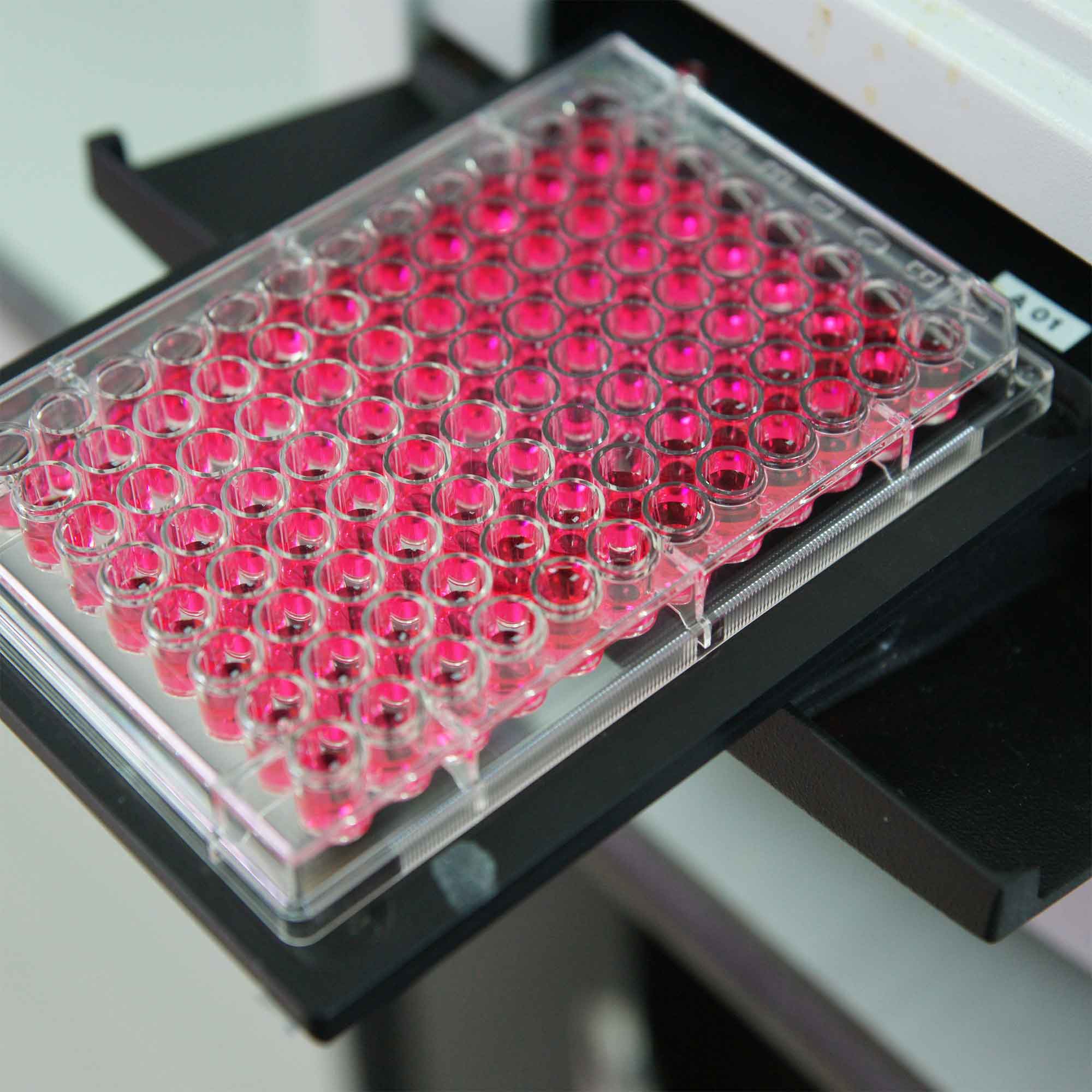

Enzyme-Linked Immunosorbent Assay (ELISA) is a widely used laboratory technique for detecting

and quantifying substances, such as proteins, hormones, and antibodies. Microplate readers, also

known as plate readers, are critical instruments in the ELISA process. They enable the detection of

color changes in the wells of a microplate, which is used to quantify the amount of analyte present

in the samples.

Proper setup and troubleshooting of a microplate reader are essential to ensure accurate and

reproducible results in ELISA assays. This article provides a comprehensive guide on how to set up

and troubleshoot your microplate reader, ensuring optimal performance and reliability.

1. Understanding the Basics of Microplate Readers

A microplate reader measures the absorbance, fluorescence, or luminescence emitted from samples

in a 96-well or 384-well microplate. In ELISA assays, the reader typically measures absorbance,

where a substrate reaction produces a color change. The microplate reader scans each well, records

the absorbance value, and generates data that can be used to determine the concentration of the

target analyte.

Microplate readers come equipped with various features, such as multiple wavelength capabilities,

high-speed reading, and precision, to ensure that ELISA assays are conducted accurately and

efficiently.

2. Proper Setup of Microplate Readers for ELISA

Setting up your microplate reader for ELISA assays requires several key steps to ensure accurate

results:

Step 1: Calibration

Before running ELISA assays, it is essential to calibrate the microplate reader. Calibration ensures the

instrument provides precise readings that align with known standards and helps eliminate sources of

error.

Perform Wavelength Calibration: Use standard solutions or calibration kits to verify the

wavelength accuracy of the reader. ELISA assays typically require measurements at 450 nm,

but you may need to adjust this depending on the assay protocol and the substrate used.

Test the Sensitivity: Ensure that the reader’s sensitivity settings are appropriate for the

ELISA assay. Most microplate readers offer adjustable gain or sensitivity settings that should

be optimized based on the assay type.

Step 2: Choose the Correct Detection Mode

Select the appropriate detection mode based on the type of ELISA you are conducting. The three

common detection modes are:

Absorbance Mode: This is the most common for colorimetric ELISA assays. Ensure that the

wavelength is set according to the substrate’s absorbance peak.

Fluorescence Mode: If the ELISA utilizes fluorescent detection, select this mode and adjust

settings for the excitation and emission wavelengths.

Luminescence Mode: For chemiluminescent assays, choose this mode and ensure that the

instrument can detect the light emitted from the reaction.

Step 3: Plate Setup

Position the Plate Correctly: Insert the microplate properly into the reader. Ensure the

correct orientation as per the reader’s specifications to ensure consistent readings across all

wells.

Set the Plate Dimensions: Input the dimensions and well configuration into the software,

typically a 96-well or 384-well plate. This helps the reader understand the plate layout and

correctly align the readings.

3. Running the ELISA Assay

Once the microplate reader is set up, you are ready to perform the ELISA assay. Here are key tips to

ensure reliable results:

Follow the ELISA Protocol: Adhere strictly to the ELISA kit instructions. Pay particular

attention to incubation times, reagent volumes, and washing steps.

Ensure Consistent Pipetting: Proper pipetting technique is crucial for accurate results. Use

calibrated pipettes to ensure precise dispensing of reagents into each well.

Avoid Cross-Contamination: Take precautions to avoid cross-contamination between wells,

such as using fresh tips and proper washing procedures.

4. Troubleshooting Common Issues with Microplate Readers

Despite careful setup, issues can arise during ELISA testing that may affect the accuracy of your

readings. Here are some common problems with microplate readers and tips on how to

troubleshoot them:

1. Inconsistent or Erratic Readings

Cause: This could be due to improper calibration, poor plate placement, or incorrect

settings.

Solution: Recalibrate the microplate reader and ensure that the correct wavelength and

detection mode are selected. Also, check if the plate is correctly inserted, ensuring it is

aligned with the reader’s optical path.

2. High or Low Absorbance Values

Cause: This could happen if the absorbance is outside the instrument's linear range,

potentially caused by improper reagent volumes or sample concentrations.

Solution: Dilute highly concentrated samples to bring them within the reader’s optimal

absorbance range (typically 0.1 – 2.0 absorbance units). Make sure you are using the right

amount of substrate and reagents as per the assay protocol.

3. Uneven Results Across Wells

Cause: This may indicate inconsistencies in the plate, such as air bubbles, uneven pipetting,

or a malfunctioning reader.

Solution: Check the plate for bubbles, especially in the wells with significant discrepancies in

readings. Also, ensure that the microplate reader is calibrated for even light distribution

across the wells.

4. Background Noise or Interference

Cause: Background noise can occur if the reader is improperly calibrated or if the samples or

reagents cause interference.

Solution: Use a blank well (no sample) for calibration, and ensure that there is no

contamination or interference from buffers or other reagents in the assay. Check for optical

interferences or scratches on the reader's optics.

5. Incorrect Wavelength Selection

Cause: Choosing the wrong wavelength can lead to inaccurate readings, especially if the

ELISA kit specifies a wavelength outside of the default settings.

Solution: Verify the wavelength used in the ELISA assay and adjust it as necessary. Most

ELISA assays recommend using wavelengths around 450 nm, but some substrates may

require different wavelengths.

5. Maintaining Microplate Readers

Regular maintenance of your microplate reader is essential to ensure reliable and accurate results.

Here are some maintenance tips:

Clean Regularly: Keep the optical components and plate tray clean to prevent dust buildup

and potential interference with readings. Use lint-free wipes and appropriate cleaning

solutions for the reader’s optics and plate holder.

Calibrate Periodically: Regular calibration, particularly for wavelength accuracy, ensures that

your reader continues to produce reliable results. Follow the manufacturer’s

recommendations for calibration frequency.

Monitor Performance: Perform routine performance checks, such as testing absorbance

with a known standard, to ensure the reader is operating correctly.

Conclusion

Setting up and troubleshooting microplate readers for ELISA assays is crucial for obtaining accurate,

reproducible results. Ensuring that your instrument is calibrated, selecting the appropriate detection

mode, and following proper setup procedures will optimize the performance of your microplate

reader. Troubleshooting common issues, such as inconsistent readings or incorrect absorbance

values, will help maintain the integrity of your assays and ensure that you achieve reliable data.

By investing in proper maintenance and calibration, you can extend the lifespan of your microplate

reader and minimize downtime. Microplate readers from Labindia Analytical provide exceptional

precision and performance for ELISA assays, helping to streamline your laboratory workflows and

improve your assay accuracy.

SEO Keywords:

Microplate Reader Setup

Troubleshooting ELISA Assays

ELISA Microplate Reader Calibration

Absorbance Measurement in ELISA

ELISA Assay Troubleshooting

Labindia Microplate Readers

ELISA Assay Optimization

Microplate Reader Maintenance